EPC General Contracting Project of 3#3200m Blast Furnace in a Steel Plant in Gansu Province

Classification:

Product Introduction

Business Details

A 3#3200m blast furnace in a steel plant in Gansu was completed and put into operation on September 28, 2012. Before shutdown, the temperature trend of thermocouples on the first and second floors of the furnace bottom is normal, and the temperature trend of thermocouples on the third and fourth floors increases sharply. The temperature of the furnace cylinder thermocouple continues to rise. The water temperature difference of No. 17 cooling wall in section 2 below No. 3 iron mouth is 0. 79 ℃, the highest is 0 .84 ℃, exceeding the alarm value of 0 .8 ℃, the water temperature difference of No. 18 cooling wall in section 2 is 0 .55 ℃, the highest is 0.64 ℃, exceeding the alarm value of 0.6 ℃, the water temperature difference of No. 6 cooling wall in section 2 is 0.6 ℃, the highest is 0 . 75 ℃, exceeding the alarm value of 0.6 ℃, the highest temperature of furnace wall thermocouple in the area below No. 3 iron mouth (point 8) 446 .4 ℃, and the highest temperature of furnace wall thermocouple in the area below No. 4 iron mouth (point 11) 584 ℃, all reaching the highest temperature in history.

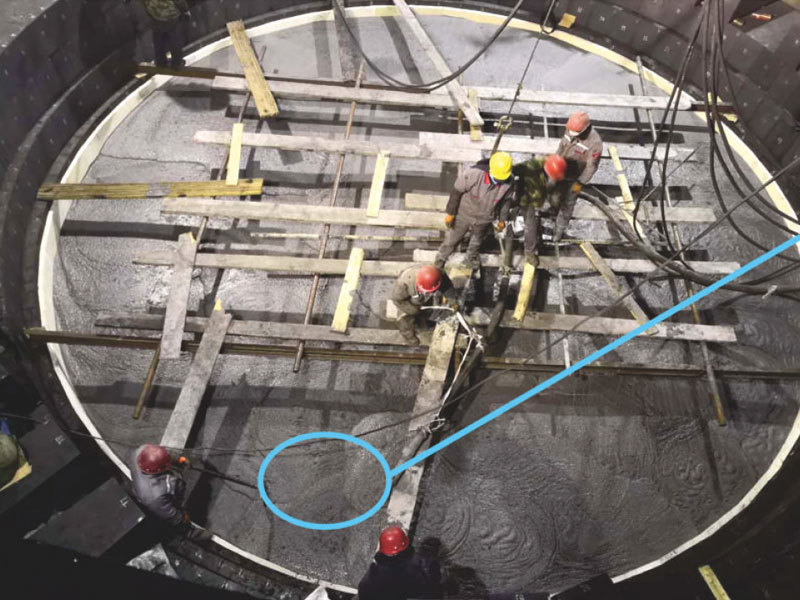

Therefore, the blast furnace began to shut down on October 9, 2021, using Huaxi EPC general contracting integrated technology to repair the furnace, after repairing the eroded carbon bricks, the furnace bottom and the furnace cylinder were poured as a whole.

For the first time, the project also adopted the "environment-friendly filling type furnace stopping and releasing residual iron method" to successfully release 611 tons of residual iron and completely release the residual iron, reaching the advanced level of releasing residual iron from large blast furnaces with the same furnace capacity.

Key words:

EPC General Contracting Project of 3#3200m Blast Furnace in a Ste

Message