Win Praise for Superb Technology in Maintenance-Integrated Solution of Improving Quality and Efficiency to Promote Green and Efficient Development of Ironmaking Blast Furnace

Time:

Apr 03,2023

Source:

Author:

In March 2023, the integrated general contracting project for the maintenance of No. 1 and No. 2 blast furnaces of a steel plant in Shanxi undertaken by Huaxi Science and Technology Group was successfully completed. The project includes sub-projects such as cooling furnace, furnace cylinder cleaning, rising pipe, falling pipe, flue spraying, cooling wall replacement, furnace throat steel brick replacement, integral pouring of tuyere belt, wet injection lining and intelligent hard press-in lining. A number of international cutting-edge patented technologies have been adopted to provide a strong guarantee for the rapid efficiency and production of blast furnaces.

West China Science and Technology Group attaches great importance to the integrated general contracting project of blast furnace maintenance. After many technical exchanges, in view of the existing problems of 1#2# blast furnace, it quickly organized the project technology department headed by Kang Zhibin, vice president of the group, to solve the technical problems in the construction process at any time. Through scientific organization, the project uses the international leading technology research and development advantages to carry forward the fine tradition of the West China Iron Army that is not afraid of difficulties and forge ahead bravely. The injection furnace type can be called exquisite! It was highly praised and praised by the leaders of the iron and steel enterprise, and issued a banner and letter of thanks symbolizing honor and recognition to Huaxi Science and Technology Group.

01 Accurate diagnosis of blast furnace erosion and integral pouring of tuyere zone

The tuyere area belongs to the high temperature zone. The technical team decided to use HXRJ-FK castable for pouring operation. No cement is added to the material. High-quality dense corundum and silicon carbide are used as the main raw materials, and silica sol imported from the United States is used as the binder. A small amount of accelerator is added to ensure the strength and reduce the impurity content of the castable. It has the properties of high temperature resistance, heat shock resistance, alkali resistance and erosion resistance, can quickly form slag skin, avoid the influence of brick joints, reduce the risk of gas channeling at the tuyere, and extend the service life of refractory materials in the tuyere area.

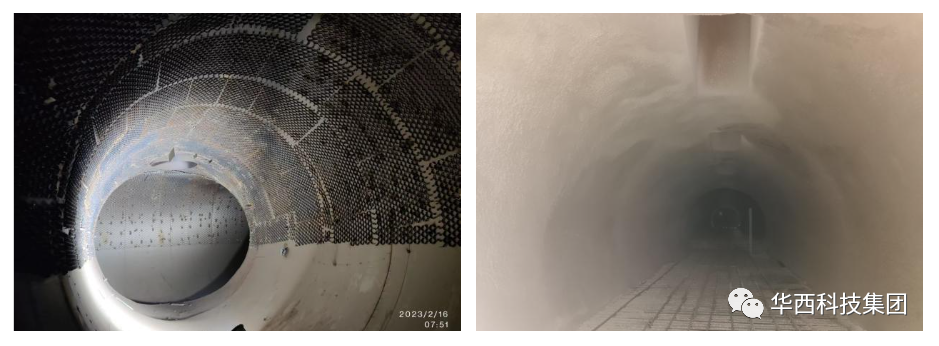

02 The furnace body is lined by wet injection to perfectly restore the design furnace type.

(1) The sixth generation of West China wet injection lining technology completely adopts sol binding, so that the binding between materials has affinity, the material structure has been further optimized, abandon the traditional water-adding binding process, completely solve the traditional process of water material binding difference, easy to fall off after bonding phenomenon.

(2) According to the construction feedback over the past few years, the construction rebound rate is less than or equal to 5%, and no dust and toxic and harmful gases are generated during injection, so as to avoid the normal operation of TRT affected by dust.

(3) The lining formed by high-pressure injection forms a high-density lining body in the blast furnace lining, with low porosity, high density, corrosion resistance and wear resistance, so as to achieve the purpose of rapid slag hanging and rapid production.

(4) Stabilize the edge airflow and improve the blast furnace smelting intensity.

(5) Rapid recovery of reasonable furnace type, increase production and reduce energy consumption are the most efficient and effective method for the longevity of blast furnace.

(6) Intelligent lining, energy saving and consumption reduction lining, blast furnace will produce nitrogen after the furnace, and the furnace wall secondary combination of continuous intelligent maintenance of furnace lining, so that the gas flow to the center of the blast furnace convergence circulation, so as to achieve the effect of energy saving and consumption reduction.

03 High temperature wear-resistant ceramic treatment technology, rising pipe, down pipe, flue for spraying treatment

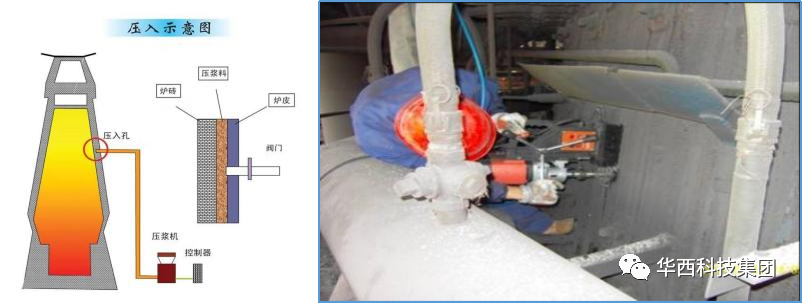

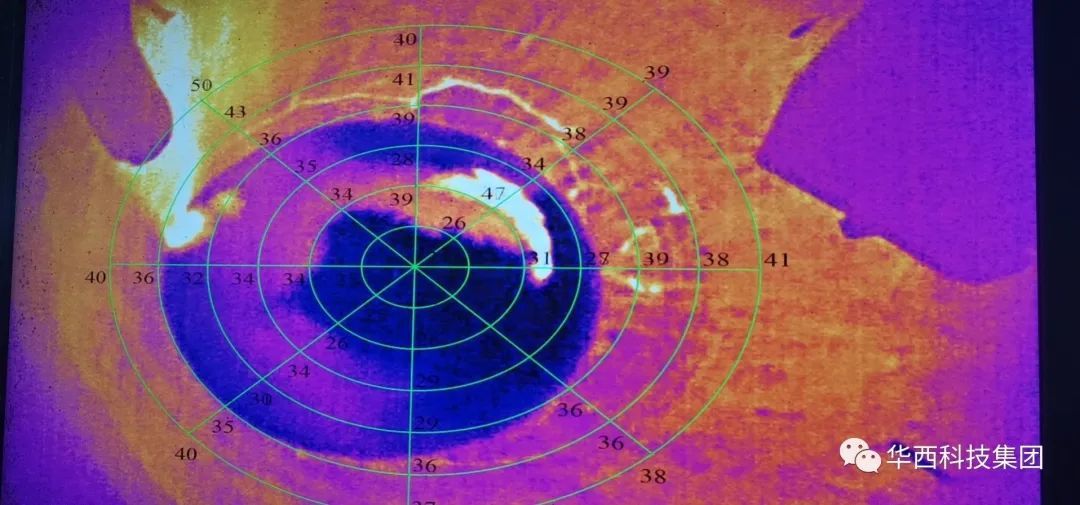

04 Adopt intelligent press-in lining technology to completely solve the "gas channeling" problem.

In view of the problems in the operation of the 1#2# blast furnace in the steel plant, the design team adopted an intelligent infrared imager to accurately locate the abnormal temperature area of the furnace skin, and decided to select a high-strength intelligent self-flow composite press-in material HX-YR for this grouting, and a press-in material HX-YR formed by reasonable grading of various micropowders and composite binders, which has the following advantages:

Good fluidity, strong permeability, gelatinous after condensation, firmly bonded with the iron shell and furnace lining, effectively filling the cracks and holes in the furnace lining to prevent gas leakage;

② Prevent the furnace shell and cooling equipment from thermal deformation and damage;

③ Keep the furnace lining wear evenly to prevent further damage to the furnace lining;

④ Emergency treatment of furnace lining repair.

05Develop a scientific oven plan and start the oven to reach production.

The integrated general contracting project for blast furnace maintenance of a steel plant in Shanxi this time is a qualitative leap in terms of scheme technology, construction technology, and material technology. It has reached the international leading level and provided high-quality for the longevity of the blast furnace. Service and guarantee, so it has been highly praised and praised by the leaders of the steel plant, and issued a letter of thanks and a banner issued by the steel plant to Huaxi Technology. Huaxi Science and Technology Group will also take this as a driving force and continue to adhere to the service concept of "taking customer demand as its own responsibility, adding credibility with high-quality service, customer satisfaction as the goal, and increasing strength with scientific and technological innovation". With new technologies, new materials, new programs and new services, we will meticulously complete all the contracted engineering service projects to protect the longevity of the blast furnace of iron and steel enterprises!

Sword front comes from sharpening, plum blossom fragrance comes from bitter cold. Huaxi people have created high-quality projects with painstaking efforts and sweat. While completing each project with high efficiency and high quality, they have also won unanimous praise from customers, which has strengthened our development confidence and innovation pace. In the future, Huaxi Science and Technology will take the development of specialization, refinement, characteristics and novelty as the focus of promoting the growth of enterprises, build the first international brand of blast furnace lining integrated service, adhere to international standards and industry benchmark, and help global iron and steel enterprises to achieve green, efficient, safe and longevity ironmaking! Let ironmaking workers peace of mind, happy, down-to-earth work!