The fuel ratio dropped by 3~5 kg/t again, ranking first in the country! Shougang Tonggang 2680m ³ Blast Furnace Smooth Iron and Steel! Wet injection lining technology to create another success!

Time:

Mar 22,2023

Source:

Author:

At 1: 06 on March 21, Shougang Tonggang 2#2680m blast furnace was successfully tapped, marking the successful completion of the overhaul project of the blast furnace and its official commissioning. After the bath fire smelting of the blast furnace, the first furnace of molten iron flows out smoothly. Iron flowers fluttered in the sound of firecrackers, iron flow gushing out along the iron mouth, a "fire dragon" meandering flow, molten iron smoothly into the iron tank. The smooth tapping of Shougang Tonggang 2# blast furnace also marks the successful practice of the sixth generation wet injection lining technology developed by West China on a large blast furnace again, creating favorable conditions for the safe, long life, green and efficient production development of the blast furnace and laying a solid foundation.

Shougang Tonggang 2#2680m blast furnace spraying adopts the sixth generation of wet injection lining technology of West China Science and Technology, and adopts three-dimensional scanning of North University of Science and Technology. According to the different working conditions of each part of the blast furnace, the reasons for corrosion resistance of each part of the blast furnace are analyzed. The upper injection material, the middle injection material and the lower injection material of the blast furnace lining are used in a targeted manner to restore the operation furnace type and achieve the optimal injection effect, it also achieves the purpose of rapid slag hanging and rapid production. All the construction personnel of Huaxi Science and Technology have been highly praised by customers for their full enthusiasm, high morale and pragmatic work style.

Wet Injection Lining Technology of Huaxi Science and Technology

The sixth generation wet injection lining technology of Huaxi Science and Technology (patent number: 201010179044.7) is one of the symbols of the development level of blast furnace long-life ironmaking technology, and is the fastest and most effective method of intelligent lining and energy saving lining. The technology to blast furnace furnace belly, furnace waist, furnace body injection, can quickly restore a reasonable furnace type, improve production, reduce energy consumption, after the furnace to produce nitrogen and furnace wall secondary combination, continuous intelligent maintenance of furnace type lining, fuel ratio and then reduce 3-5 kg/t, blast furnace performance of various indicators is good, adopted by domestic and foreign steel enterprises. At present, the market share of Huaxi spraying project is 69.76, firmly occupying the first place in China!

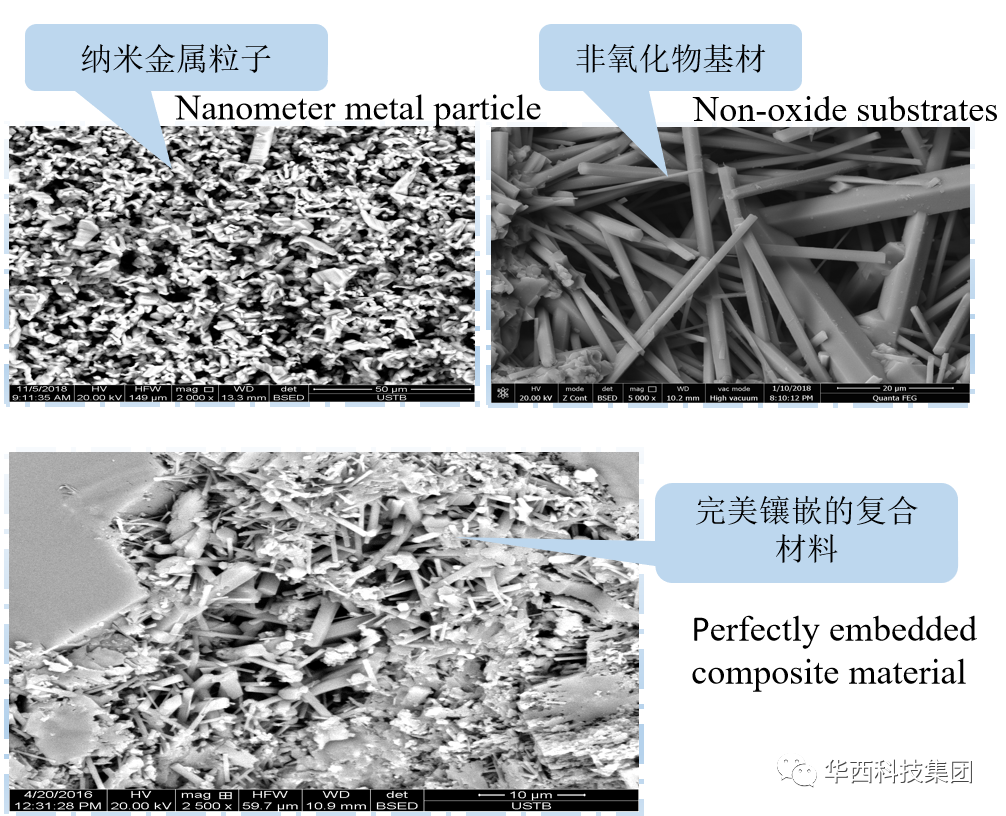

Research and development concept of high-strength composite injection material for Theron

(1) The use of metal (Si/Al) ductility to achieve plastic forming, the use of nitriding and reducing atmosphere in the blast furnace to achieve the use of in situ synthesis of high-temperature enhanced phase (Si3N4/SiAlON), and non-oxide substrate to form a perfect mosaic structure, while achieving:

◆ Excellent resistance to chemical erosion

The use of the process with self-repair function

◆Good thermal shock resistance

(2) With the metal-non-oxide composite material system as the substrate, through non-oxide surface modification, the use of sol-gel molding process to achieve:

◆Good liquidity

◆Fast drying performance

◆ Overall stability after drying

Advantages of the sixth generation wet injection lining technology

(1) The sixth generation of wet injection lining technology of Huaxi Science and Technology completely adopts sol binding, so that the binding between materials has affinity, the material structure has been further optimized, abandoning the traditional water binding process, completely solving the traditional process of poor water binding, easy to fall off after bonding phenomenon.

(2) According to the construction feedback over the past few years, the construction rebound rate is less than or equal to 5%, and no dust and toxic and harmful gases are generated during injection, so as to avoid the normal operation of TRT affected by dust.

(3) The lining formed by high-pressure injection forms a high-density lining body in the blast furnace lining, with low porosity, high density, corrosion resistance and wear resistance, so as to achieve the purpose of rapid slag hanging and rapid production.

(4) Stabilize the edge airflow and improve the blast furnace smelting intensity.

(5) Rapid recovery of reasonable furnace type, increase production and reduce energy consumption are the most efficient and effective method for the longevity of blast furnace.

(6) Intelligent lining, energy saving and consumption reduction lining, blast furnace will produce nitrogen after the furnace, and the furnace wall secondary combination of continuous intelligent maintenance of furnace lining, so that the gas flow to the center of the blast furnace convergence circulation, so as to achieve the effect of energy saving and consumption reduction. Statistics on the production data of iron and steel enterprises show that the coke reduction ratio of the sixth generation wet injection lining technology in West China can reach up to 7%, the utilization coefficient is increased, and the average direct profit benefit of molten iron is nearly 50 million yuan!

Huaxi people have created high-quality projects with painstaking efforts and sweat. While completing each project with high efficiency and high quality, they have also won unanimous praise from customers, which has strengthened our development confidence and innovation pace. In the future, Huaxi Science and Technology will focus on the development of specialization, refinement, characteristics and novelty as the focus of promoting the growth of enterprises, casting the first brand of "specialization and innovation" in the ironmaking refractory industry, adhering to international standards and industry benchmarking, and helping global iron and steel enterprises to achieve green, efficient, safe and longevity ironmaking! Let ironmaking workers peace of mind, happy, down-to-earth work!