[Quality West China Frequency Reaches New High] West China Science and Technology's World's First Integrated Whole Furnace Pouring Technology Successfully Applied in 2777m Grade Large New Blast Furnace!

Time:

Jun 21,2022

Source:

Author:

Summer good news, blast furnace ignition passion burning. Success in one fell swoop, Longmen jump, Huaxi good performance reputation. On May 26, the 2777m ³ blast furnace construction project of Linyi Iron and Steel Investment Group Special Steel Co., Ltd., undertaken by West China Science and Technology Group, was successfully baked and entered the trial heating stage. It marks that Huaxi Science and Technology has successfully completed the task of integrated whole furnace pouring construction, witnessed the brilliant moment of high-quality development of Linyi Steel Investment Special Steel, and rewritten a new chapter in China's steel industry!

The construction of Linyi Steel Investment Special Steel 2777m ³ blast furnace is listed as the No. 2 major construction project in Shandong Province in 2020. It is the call of Linyi Municipal Government to respond to the national supply-side structural reform and the structural adjustment of the steel industry. After the completion of the project, it is of great significance to expand the local economic scale and accelerate the conversion of new and old kinetic energy. The construction scope of Huaxi Science and Technology Group includes the pouring construction of the bottom, hearth, tuyere and cooling wall of the newly-built 2777m blast furnace. The pouring construction will start on April 15, 2022. The planned construction period is 10 days, with tight time and heavy tasks. It is another new challenge for Huaxi Science and Technology.

The construction of Linyi Steel Investment Special Steel 2777m ³ blast furnace is listed as the No. 2 major construction project in Shandong Province in 2020. It is the call of Linyi Municipal Government to respond to the national supply-side structural reform and the structural adjustment of the steel industry. After the completion of the project, it is of great significance to expand the local economic scale and accelerate the conversion of new and old kinetic energy. The construction scope of Huaxi Science and Technology Group includes the pouring construction of the bottom, hearth, tuyere and cooling wall of the newly-built 2777m blast furnace. The pouring construction will start on April 15, 2022. The planned construction period is 10 days, with tight time and heavy tasks. It is another new challenge for Huaxi Science and Technology.

Although thousands of people have worked hard, they have blown out the crazy sand before they reach gold. West China Science and Technology Group quickly formed a technical expert group with commander-in-chief Kang Zhibin, chief technical officer Xu Jingdong, and engineering design expert Qu Meiqiang, and appointed more than 80 technical workers to participate in the project construction. The technical team went deep into the front line of construction, strictly controlled the quality of the project, overcome the construction difficulties, and worked out a scientific, efficient and practical pouring schedule to advance the construction progress of the project in an orderly manner. During the construction, the epidemic was raging and faced many difficulties, such as traffic stagnation, equipment failure to transport, and lack of accommodation for personnel. However, all the construction personnel of West China Science and Technology concentrated their efforts and fought day and night. With full enthusiasm, high morale and pragmatic style, the new blast furnace project of Linyi Steel Investment Special Steel 2777m was successfully baked on time and according to the quality.

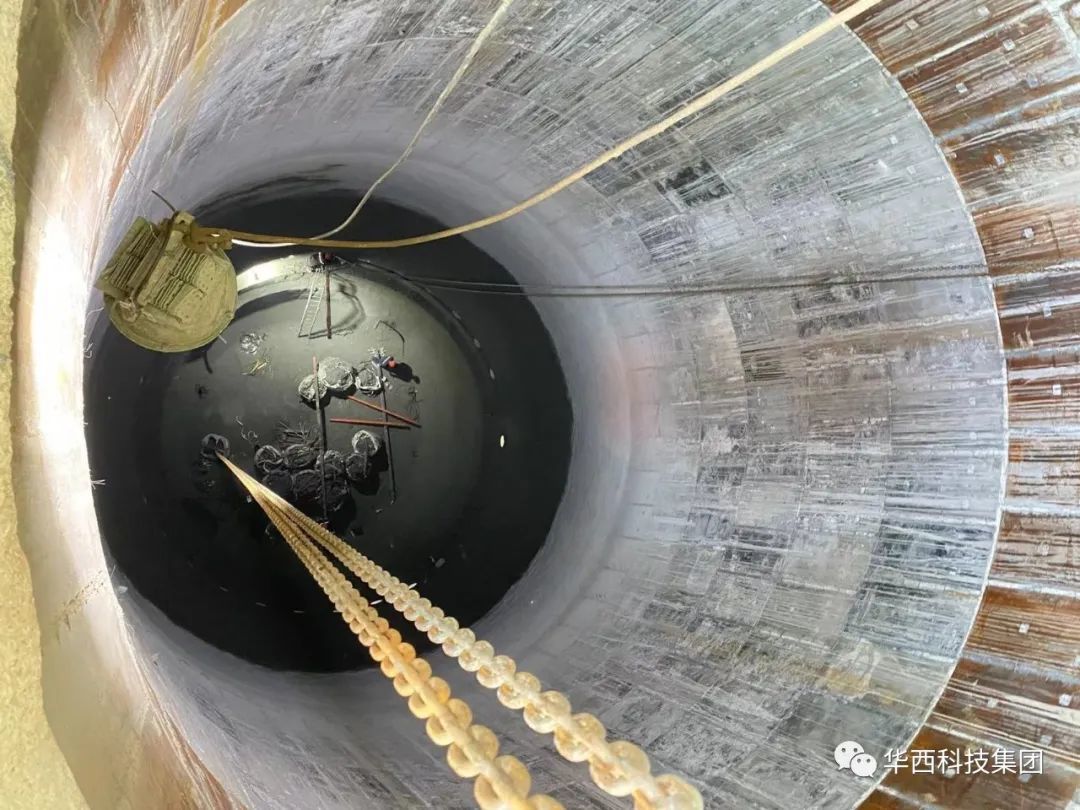

Schematic diagram of integrated whole furnace pouring

The technical team of Huaxi Science and Technology Group has tailored a complete set of pouring scheme for Linyi Steel's special investment of 2777m new blast furnace. Among them, several advanced patented technologies independently developed by Huaxi Science and Technology and pioneered in the world are adopted:

Integral Pouring Technology of Blast Furnace Hearth

Patent number: ZL 201610353176.4

The new long-life blast furnace hearth overall pouring technology, according to the different erosion mechanism of each part of the blast furnace hearth, uses 4 kinds of carbon-nitrogen composite pouring materials, with a total consumption of nearly 800 tons. The whole pouring molding, seamless docking, prevent wear iron corrosion resistance is good, furnace cylinder pouring layer and ring carbon brick contact, thermal conductivity is very high.

HX series sol-bonded sialon carbon-nitrogen composite castables

Patent number: ZL 201811449053.6

Hearth casting uses HX series sol combined with sialon carbon and nitrogen composite castable with high temperature resistance, slag iron erosion resistance, thermal shock resistance and erosion resistance. all materials do not add cement, and high-purity dense corundum and silicon carbide are used as main raw materials, and zirconia, boron nitride and α-Al are added.2O3›Si3N4Such as a variety of ultra-fine powder matrix materials, to the United States TRE imported composite sol as a binder, to ensure the strength of the same time, to minimize the impurity content of the material, high temperature to form a Thalon structure, which has excellent corrosion resistance.

At the same time, the furnace cylinder pouring construction adopts the self-flow pouring process independently developed by Huaxi. The pouring body completely eliminates the two major gaps of traditional ceramic cups (the gap between ceramic bricks and the large gap between ceramic cups and carbon bricks), prevents the erosion of carbon bricks by harmful elements such as water vapor and alkali metals during blast furnace production, and can leave the high-temperature sharp temperature drop zone in the castable, reducing the internal temperature of carbon bricks to below 800 ℃, reduce the thermal stress in the carbon brick, reduce the appearance of carbon brick ring crack and embrittlement layer, effectively protect the carbon brick, and maintain the thermal conductivity of the carbon brick.

At the same time, the furnace cylinder pouring construction adopts the self-flow pouring process independently developed by Huaxi. The pouring body completely eliminates the two major gaps of traditional ceramic cups (the gap between ceramic bricks and the large gap between ceramic cups and carbon bricks), prevents the erosion of carbon bricks by harmful elements such as water vapor and alkali metals during blast furnace production, and can leave the high-temperature sharp temperature drop zone in the castable, reducing the internal temperature of carbon bricks to below 800 ℃, reduce the thermal stress in the carbon brick, reduce the appearance of carbon brick ring crack and embrittlement layer, effectively protect the carbon brick, and maintain the thermal conductivity of the carbon brick.

Cooling Wall Hot Surface Casting Technology

Patent number: ZL 201811449733.8

Huaxi's original new cooling wall hot surface casting technology has two construction methods, one is to cast the mold outside the furnace, the other is to cast the mold inside the furnace, combined with the actual situation on site to decide to use the outside pouring method. The high-strength composite material cast on the hot surface of the cooling stave is divided into the lower part using Huaxi corundum silicon carbide castable (HXNM-TICTC) and the upper part using Huaxi ceramic corundum (HXNM-GLTC) castable.

The castable at the bottom of the furnace belly-furnace body is mainly silicon carbide, adding steel fiber and corundum, with good thermal conductivity; high toughness; high strength; resistance to slag iron erosion and alkali erosion.

The casting material in the upper part of the furnace body is mainly corundum, adding metal steel fiber, which is wear-resistant, high strength, good toughness, mechanical wear resistance and thermal shock resistance.

The cooling stave hot surface pouring technology takes advantage of the respective advantages of metal materials and non-metallic materials. It has excellent performance, easy slag skin, and convenient installation and use on site. It can form slag skin well for the hot surface of the cooling stave and improve the protection of the cooling stave. Performance, fundamentally solve the problem of water leakage and damage of the cooling system, greatly increase the service life of the cooling stave, and realize the efficient, safe and stable operation of the blast furnace.

The 2777m ³ new blast furnace project of Linyi Steel Investment Special Steel is a qualitative leap in terms of scheme technology, construction technology and material technology, reaching the international leading level and providing high-quality service and guarantee for the longevity of blast furnace. Therefore, it has been highly praised by the leaders of Linyi Steel Investment and sent us a letter of commendation in the first place. Huaxi Science and Technology Group will also take this as a driving force and continue to adhere to the service concept of "taking customer demand as its own responsibility, adding credibility with high-quality service, customer satisfaction as the goal, and increasing strength with scientific and technological innovation". With new technologies, new materials, new programs and new services, we will meticulously complete all the contracted engineering service projects to protect the longevity of the blast furnace of iron and steel enterprises!

Huaxi people have created high-quality projects with painstaking efforts and sweat. While completing each project with high efficiency and high quality, they have also won unanimous praise from customers and reaped the joy of success, which has strengthened our development Confidence and innovation pace, we will uphold the technological innovation service concept of "international standards, industry benchmarks, high efficiency and safety, continue to improve technical quality, product quality, engineering quality, and service quality, as always, to provide first-class products and services for domestic and foreign steel users, and make unremitting efforts to build the shining brand of" Quality Huaxi!